Recently, the Inimco team finished a Proof of Concept (PoC) at a client-company in which the power of the rule engine, that is an integral part of the Inimco.Facts platform, was successfully demonstrated.

How to measure the immeasurable?

The customer’s challenge was quite complex. The company extracted material from raw materials that was resold to their customers as an essential ingredient in these customers’ production cycle. But there was also an important by-product that provided an additional source of revenue. It was easy enough to measure the output of the first, by using the OPC UA connected PLCs. But measuring the yield of the by-product was nigh on impossible. Before our PoC, the company had to manually make estimates, based on an XLS file with theoretical calculations.

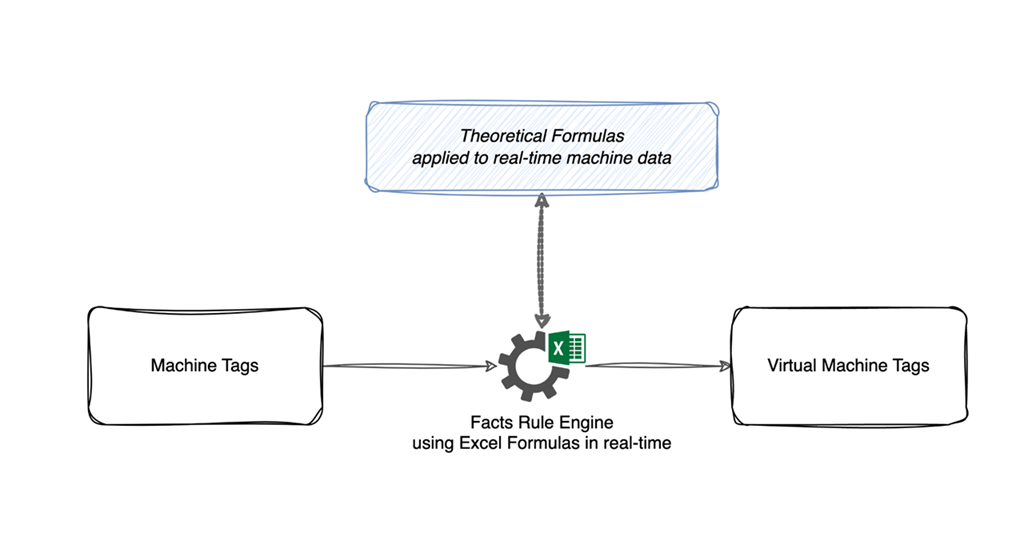

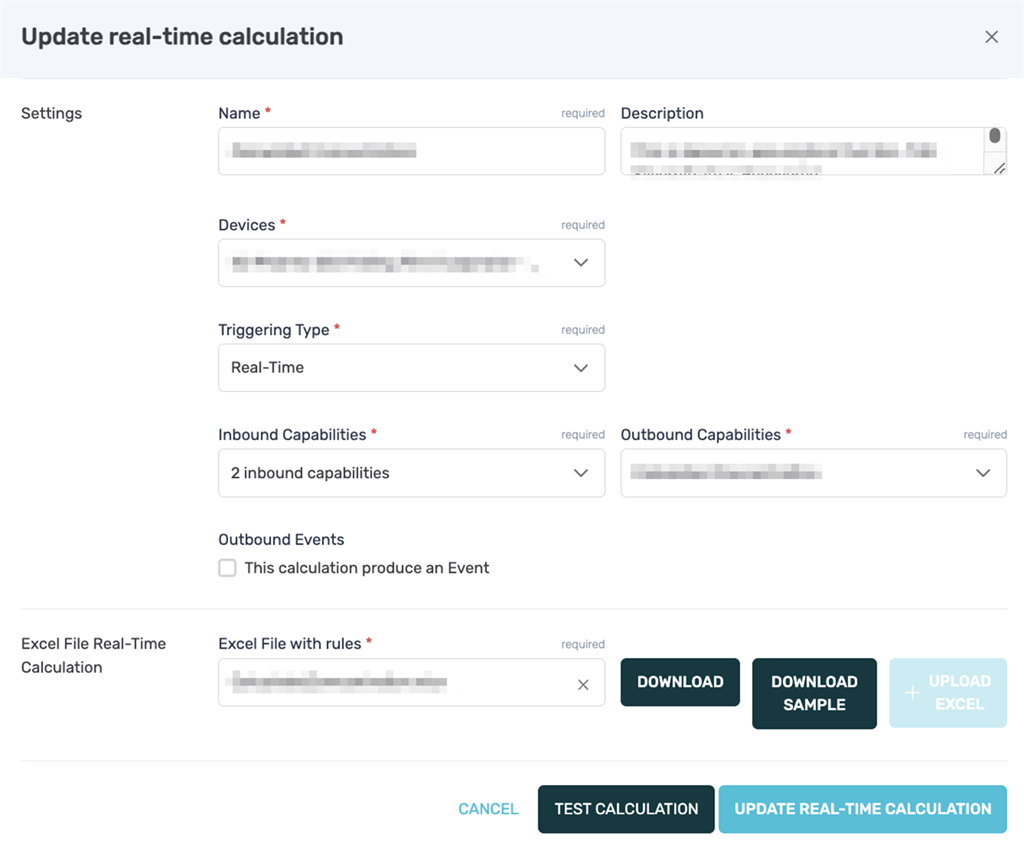

By using the rules engine inside Inimco.Facts, we were able to combine real-time data from their PLCs with the theoretical model. To do that, we uploaded the XLS file into the rule engine, which unburdened the customer from any rework or recalculations. What we had done, in fact, was to consider the combination of real-time data and the theoretical calculations as a ‘virtual sensor’. The use of virtual sensors offers great opportunities to measure what is, in reality, not measurable, for instance when it is not possible to install a physical sensor inside a machine.

Better insights into overall efficiency

Building this virtual sensor would have been impossible without the rule engine inside Inimco.Facts – one of the differentiating features of our platform. Without the rule engine, combining these real-time data with the theoretical model and displaying them in the overall dashboard the customer uses, would have been an intensive development effort. Thanks to the rule engine, it took no longer than a couple of hours.

Thanks to the integration, the customer was able to add an extra data point in their dashboard, enabling them to measure their Overall Equipment Effectiveness (OEE) more accurately. Having this complete overview provides them with a better insight into the real-time status of a machine, the energy they are using and the yield of their equipment. It is now easier to notice deviations from the standard condition and adjust the settings to get optimal yield.

Thanks to the rule engine inside Inimco.Facts, we were able – proverbially – to kill three birds with one stone:

- - We were able to quickly display real-time data in a dashboard

- - These data were correlated with a theoretical model and represented a virtual sensor

- - Having this extra data source offers our customer better insights into their OEE

Interested in finding out how the Inimco.Facts rule engine can also empower your production cycle? Contact us.